In the transportation industry, safety is paramount, particularly in rail transport where visibility can be the difference between a normal day and a catastrophic event. The Federal Railroad Administration (FRA) in the United States mandates certain safety measures to enhance the visibility of rail cars. One such measure is the application of reflective tape, a crucial component for nighttime visibility and safety. 3M, a global leader in adhesive and reflective materials, offers FRA-compliant reflective tapes specifically designed for rail cars. This article explores the benefits, requirements, and practical application of 3M FRA reflective tape on rail cars.

The Importance of Reflective Tape

Reflective tape increases the visibility of rail cars significantly during low light conditions and at night. This is especially important at railroad crossings where trains are near automobiles. The tape works by reflecting light from headlights and other light sources back towards the source, making the rail car clearly visible from a distance. This not only helps in preventing collisions but also aids in the identification and tracking of rail cars across vast rail networks.

FRA 224 Regulations (summary)

The Federal Railroad Administration (FRA) sets stringent rules for the use and quality of reflective tape on rail cars to improve safety and visibility. According to FRA regulations, bright yellow or white reflective tape is needed on both the ends and sides of freight cars to assure they can be seen from long distances when light shines on them. The tape needs to be rugged, weather resistant, and keep its reflective ability even in inclement conditions. It must also bear the FRA 224 logo on the tape to designate it as compliant. FRA 224 regulations specify that this reflective material must be placed either vertically or horizontally along the sides of the rail car, following certain size and placement rules. At each end of the rail car, there must be at least one 4″ x 36″ strip, or two 4″ x 18″ strips put together, with additional 18″ strips placed every 12 feet between these larger strips to keep visibility consistent along the whole car. (Note – before applying any regulated tape, make sure to read the regulations pertaining to application in full to make sure you are in compliance)

3M’s Reflective Tapes

3M FRA reflective tape, based on their popular 983 film, exceeds FRA standards. These tapes are engineered to be highly reflective, durable, and resistant to weathering, including resistance to water, dirt, and UV light degradation. Using and properly caring for these compliant tapes on rail cars not only meets legal safety standards but also enhances the longevity and visibility of the markings.

Application of 3M Reflective Tape

The application of 3M FRA reflective tape is straightforward but requires attention to detail. The surface of the rail car must be clean and free of any dirt, grease, or debris to ensure the adhesive bonds well. The tape is then applied evenly across the required areas, avoiding any creases or bubbles that could impair reflectivity. It’s crucial that the tape is applied in continuous strips to maximize visibility.

Maintenance and Inspection

Regular maintenance and inspection are essential to ensure that the reflective tape maintains its effectiveness. The rail cars should be inspected periodically to check for any damage to the tape, such as peeling, cracking, or fading. Replacement of the tape should be done promptly to maintain compliance with FRA regulations and to ensure safety and avoid fines by the FRA. Rail Cars should never leave a rail depot without properly applied compliant FRA tape installed.

Conclusion

The use of 3M FRA reflective tape on rail cars is a critical safety measure that enhances visibility, thereby reducing the risk of accidents and improving the overall safety of rail transportation. Rail companies are encouraged to not only comply with FRA regulations but to consider the application of reflective tape as a proactive safety strategy. With products like those from 3M, rail operators can ensure that their fleets are visible and compliant, operating safely across the thousands of miles they travel.

Copy of FRA Placement Regulation Below –

§224.101 General requirements.

All rail freight rolling stock subject to this part shall be equipped with retroreflective sheeting that conforms to the requirements of this part. Notwithstanding any other provision of this chapter, the application, inspection, and maintenance of that sheeting shall be conducted in accordance with this subpart or in accordance with an alternative standard providing at least an equivalent level of safety after special approval of FRA under §224.15.

§224.103 Characteristics of retroreflective sheeting.

(a) Construction. Retroreflective sheeting applied pursuant to this part shall consist of a smooth, flat, transparent exterior film with microprismatic retroreflective elements embedded in or suspended beneath the film so as to form a non-exposed retroreflective optical system.

(b) Color. Retroreflective sheeting applied pursuant to this part shall be yellow, fluorescent yellow, or white as specified by the chromaticity coordinates of ASTM International’s Standard D 4956-04, “Standard Specification for Retroreflective Sheeting for Traffic Control.” The Director of the Federal Register approves the incorporation by reference of this standard in this section in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. You may obtain a copy of the incorporated standard from ASTM International, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, PA 19428-2959 or at http://www.astm.org.You may inspect a copy of the incorporated standard at the Federal Railroad Administration, Docket Clerk, 1200 New Jersey Avenue, SE., Washington, DC 20590 or at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030.

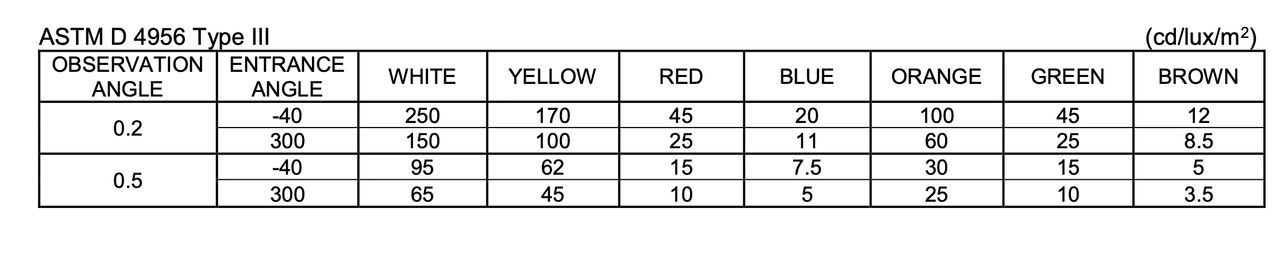

(c) Performance. Retroreflective sheeting applied pursuant to this part shall meet the requirements of ASTM D 4956-04, for Type V Sheeting if metalized or Type VII Sheeting if non-metalized, except for the initial minimum values of the coefficient of retroreflection, and shall, as initially applied, meet the minimum values for the coefficient of retroreflection specified in Table 1 of this subpart.

[70 FR 62176, Oct. 28, 2005, as amended at 74 FR 25173, May 27, 2009]

Table 1 to Subpart B of Part 224—Minimum Coefficient of Retroreflection (RA) (in Candela/Lux/Meter2) Requirement for Retroreflective Sheeting (Minimum Photometric Performance Requirements)

c(d) Certification. The characters “FRA-224”, constituting the manufacturer’s certification that the retroreflective sheeting conforms to the requirements of paragraphs (a) through (c) of this section, shall appear at least once on the exposed surface of each piece of sheeting in the final application. The characters shall be a minimum of three millimeters high, and shall be permanently stamped, etched, molded, or printed within the product and each certification shall be spaced no more than four inches apart.

(e) Different standards Under 224.15, a railroad or owner of freight rolling stock may petition the Associate Administrator to approve a different safety-enhancing technology. Any such petition must include enough data and analysis to show that the technology will be visible and last at least as long as the sheeting described in paragraphs (a) through (c) applied in accordance with this part. It will also show that the technology will present a recognizable visual target that is in line with freight rolling stock with retroreflective sheeting that meets the technical requirements of this part to give motorists the intended warning.

§224.105 Sheeting dimensions and quantity.

Retroreflective sheeting shall be applied along the length of each railroad freight car and locomotive side as described in §224.106. Unless otherwise specified, retroreflective sheeting applied under this part shall be applied in strips 4 inches wide and 18 or 36 inches long, as practicable. The amount of retroreflective sheeting to be applied to each car or locomotive subject to this part is dependent on the length of the car or locomotive and the color of the sheeting. For purposes of this part, the length of a railroad freight car or locomotive is measured from endsill to endsill, exclusive of the coupler and draft gear. Each side of a railroad freight car subject to this part, including each unit of multi-unit cars, and each side of a locomotive subject to this part must be equipped with at least the minimum amount of retroreflective sheeting specified in Table 2 of this subpart.

1Freight cars or locomotives over 100 ft. in length must be equipped with an additional one-half a square foot of sheeting on each side for every additional 10 feet of length.

§224.106 Location of retroreflective sheeting.

(A) Freight trains on railroads. The Associate Administrator has approved a uniform industry standard that calls for the distribution of material along the length of each car and as near as reasonably possible to 42 inches above the top of rail to be used to apply the retroreflective sheeting along the length of each railroad freight car side. The standards outlined in this subpart must be followed if such a standard is not proposed by business or adopted by the Associate Administrator. The retroreflective sheeting used in accordance with this item must be placed away from any fixtures and equipment, such as pipes, ladders, and other safety appliances, that could obstruct its sight. Bolts, rivets, door hinges, and other discontinuous surfaces that might prevent the retroreflective sheeting from sticking to the car sides are not required to have discontinuous surfaces covered with retroreflective sheeting. Additionally, car stencils and markings that are already present or necessary need not be covered with retroreflective sheeting. 4×18 and 4×36 inch strips of retroreflective material may be cut into 4×9 inch strips and applied on either side of the appurtenance, discontinuous surface, or existing or required car markings or stencils, as is practical, if it is necessary to avoid appurtenances, discontinuous surfaces, or existing or required car markings or stencils. Retroreflective sheeting must be installed along the sides of freight rolling stock, unless otherwise specified, as practically as possible, at intervals not to exceed every 12 feet. Due to existing stencils, adornments, or discontinuous surfaces, it may not be practical to apply retroreflective sheeting every 12 feet. In this case, the sheeting must be applied at the minimum feasible spacing.

(1) General rule. On railroad freight cars other than flat cars and tank cars, retroreflective sheeting shall be applied in either a vertical or horizontal pattern along the length of the car sides, with the bottom edge of the sheeting as close as practicable to 42 inches above the top of rail. Retroreflective sheeting shall not be applied below the side sill.

(i) Vertical application. If retroreflective sheeting is applied in a vertical pattern, at least one 4×36 inch strip or two 4×18 inch strips, one above the other, shall be applied as close to each end of the car as practicable. Between these two vertical end strips, a minimum of one 4×18 inch strip shall be applied at least every 12 feet, as practicable. See Figures 1, 2 and 3.

(ii) Horizontal application. If retroreflective sheeting is applied in a horizontal pattern, at least one 4×36 inch strip, or two 4×18 inch strips, one above or next to the other, shall be applied as close to each end of the car as practicable. Between these end strips, a minimum of one 4×18 inch strip shall be applied at least every 12 feet, as practicable. See Figures 4, 5, and 6.

(2) Tank cars. On tank cars, retroreflective sheeting shall be applied vertically to each car side and centered on the horizontal centerline of the tank, or as near as practicable. If it is not practicable to safely apply the sheeting centered vertically about the horizontal centerline of the tank, the sheeting may be applied vertically with its top edge no lower than the horizontal centerline of the tank. A minimum of either one 4×36 inch strip or two 4×18 inch strips, one above the other, shall be applied as close to each end of the car as practicable. Between these two end strips, a minimum of one 4×18 inch strip shall be applied at least every 12 feet, as practicable. Retroreflective sheeting applied under this part shall not be located in the spillage area directly beneath the manway used to load and unload the tank. See Figures 7 and 8.

(3) Flat cars. On flat cars, retroreflective sheeting shall be applied in a horizontal pattern along the length of the side sill with the bottom edge of the sheeting no lower than the bottom of the side sill and the top edge of the sheeting no higher than the top of the car deck or floor. At least two 4×18 inch strips, one above the other, shall be applied as close to each end of the car as practicable. If the side sill is less than 8 inches wide, one 4×36 inch strip, or two 4×18 inch strips may be applied one next to the other, dividing the strips into nine inch segments as necessary in accordance with paragraph (a) of this section. Between the two end strips, a minimum of one 4×18 inch strip shall be applied at least every 12 feet, as practicable. See Figure 9. If a car has a separate rack structure, retroreflective sheeting may be applied to the flat car portion only in accordance with the requirements of this section. For cars without continuous side sills, retroreflective sheeting may be applied to other surfaces inboard of the sides, such as the center sill, provided that the sheeting is not obscured by other components.

(4) Cars of special construction. This paragraph applies to any car the design of which is not compatible with the patterns of application otherwise provided in this section. Retroreflective sheeting shall conform as closely as practicable to the requirements of paragraphs (a)(1) through (a)(3) of this section and shall have the minimum amount of sheeting described in §224.105 distributed along the length of each car side.

(b) Locomotives. Locomotives subject to this part shall be equipped with at least the minimum amounts of retroreflective sheeting required by §224.105 either in strips four inches wide and 18 or 36 inches long and spaced as uniformly as practicable along the length of the locomotive sides, or in one continuous strip, at least four inches wide, along the length of the locomotive. Retroreflective sheeting applied to locomotive sides shall be applied as close as practicable to 42 inches from the top of the rail.